If you look at that close, it might seem that the lines are not sometimes cut totally, but that's actually just some leftover copper/substrate dust the vacuum didn't pick up that gets washed away after drilling & cutout and before you start soldering the board. This one was very early on, some number of days after getting the machine and slowly learning to use it, the same design seen under the ruler was a total disaster, not using autoleveling, but this one was nearly perfect when it comes to the isolation milling: To get an idea what to expect, here are some (more or less randomly picked) examples of a few boards (nothing really complicated here though, and probably not in chronological order): There are other models too, usually named after the work area they have (X- and Y-planes, Z-plane movement is usually not indicated in the name), for example, CNC 2418 has a X/Y -workplane of about 240 by 180 millimeters.

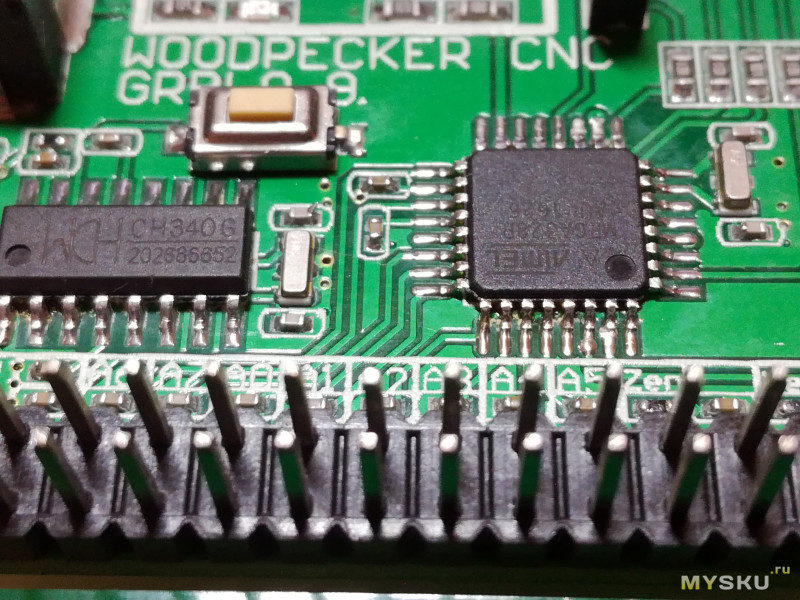

I got a cheap Chinese CNC 2418 about two years ago, in the fall of 2016, and I haven't regretted it. I don't claim what I will describe (in the later posts, this is just the preface) is the only or "best" way to mill out PCBs, but I've done way over a hundred boards in total (maybe something like 70+ different designs, largest "batch" has been 40 boards of single small design, the IR-led / photodiode transmit/receiver boards for the robots) with the CNC and have developed my own "method" which makes good boards almost all of the time, and when it doesn't, it's usually either due to dull V-bit, trying to "save time" by skimping on the autoleveling grid size or a mistake in design, or a combination of these.

This is a "tutorial" I've been meaning to write for a good while (like.

0 kommentar(er)

0 kommentar(er)